Compressed Air

Our compressed air system is a utility

with generation, distribution, and points of use.

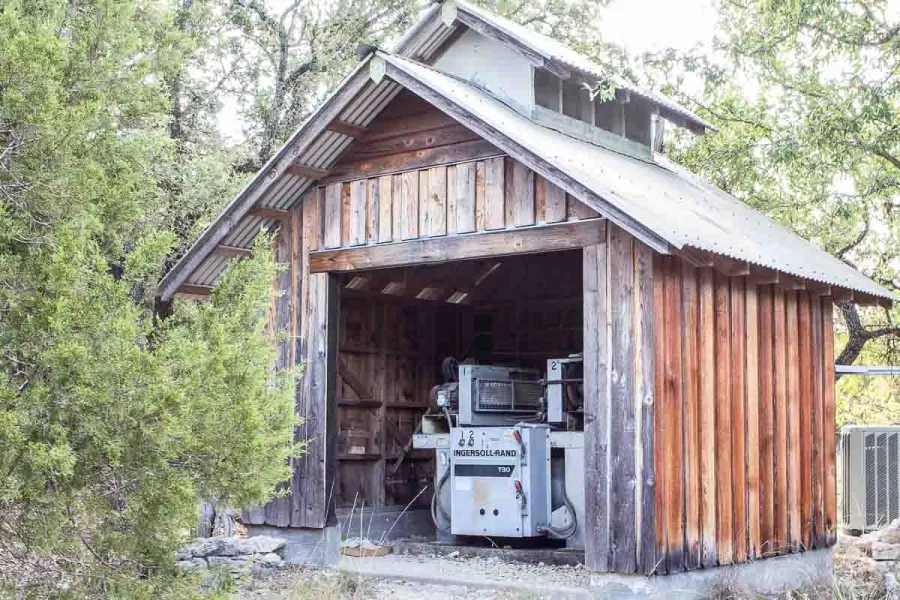

The Air Compressor

For many years, we used a portable air compressor for a few limited tasks. The quest to reduce time and stress in sanding led us to invest in a stationary compressor. Air sanders are lighter, more powerful, and more nimble than electric sanders. The change to them was imperative and profound. They use lots of air, requiring ample horsepower at the compressor. There are other uses and benefits to having plenty of clean dry air under pressure.

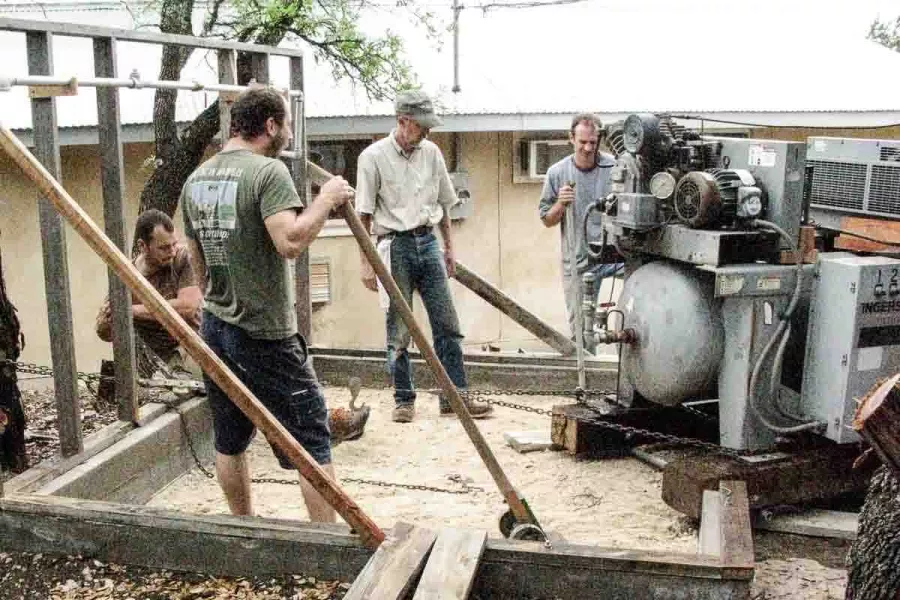

Building a building and moving the compressor to it were laborious, and fun.

Distribution

Leslie's father and grandfather were plumbers. We inherited the tools. With them, we cut, threaded, and installed a network of pipes designed to engineering standards. We built a loop of large diameter pipe around the outside wall of the shop that slopes to a drain. Pipes go up from the loop and then down to the tool or device. Any water from condensation stays in the loop and is removed at the drain.

Uses for the Air

Air sanders give us better finishes in less time with less dust than electric sanders and are easier on the hands. With a device using a venturi, we can create a suction to hold parts tightly in jigs and fixtures (a vacuum from compressed air). Air pressure moves pistons, opens valves, operates drills, and drives tacks.