The front legs on our dining chairs pass through the seats and are wedged. To produce round tenons on these legs, we first cut square ones on the table saw to remove most of the wood.

We have modified a two spindle Newton boring machine to cut round tenons. This machine was made for doweling. We changed the pulleys to slow the rotation and built fixtures to hold the various legs that we tenon. Austin is adjusting the fixture to center the cutter on the tenon.

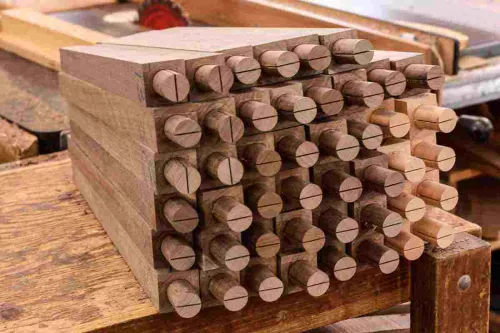

After tenoning, we taper the legs and saw a kerf to receive a wedge at assembly.

The tenon shoulders are cut at 2 degrees to flair the legs.