This is the most finicky, persnickety, frustrating, and aggravating way I know to join a case. It requires precision, patience, and painstaking beyond anything else we do. We do it because the display of exacting craftsmanship and the strength of the cabinet is unsurpassed.

We still lose money at it. But with this latest chest for drawers, assembled today, we have turned a corner — around exasperation and on the stretch to breakeven.

Among the hard things about it:

- The panels of solid wood must be flat, square, and true to thickness, width, and length — within a very few thousandths.

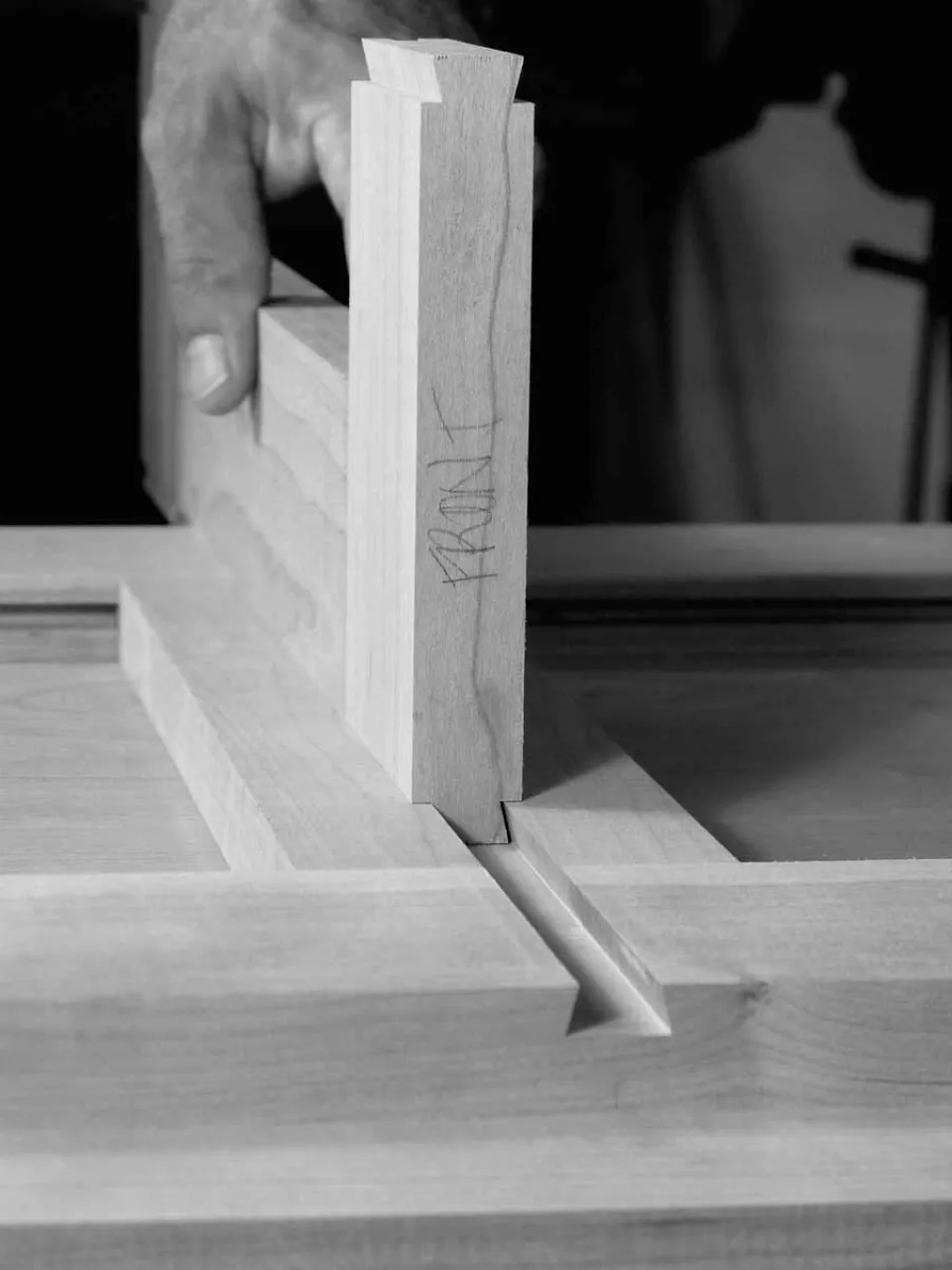

- The dovetail grooves across the panels must be true to depth and taper, again within a very few thousandths. They must be square to the face, on layout, and in line with their mates at the front and back of the panels.

- The dovetail pins on the ends of the panels must be mirror images of the grooves — yet smaller without being a hair too small.

- A dovetail pin must slide into its groove and become tight along its entire length just as the faces of the panels line up.

- A joint that slides and fits dry will be tight when glue swells the wood.

Among the new developments we made with this case:

- We figured out a superior way to lay out the guide lines on the panels.

- We tuned up the grooving fixture that guides the router across the panels.

- We remade the tapered carriage that guides the panels over the router table.

The assembled case is interlocked, rock-solid rigid, and square. You can’t shake it.